A new way to liquefy natural gas using only moderate pressure (80 to 90 Bar) and conventional refrigeration (-50 C to -60 C). Not Cryogenic temperatures. So, “stripping” of the gas is [not] required. De-hydration is required. Therefore, compared to conventional LNG, OPEX costs to liquefy natural gas as Pressurized-Liquefied Natural Gas (P-LNG) are reduced by 75%. CAPEX costs are slashed by 90%.

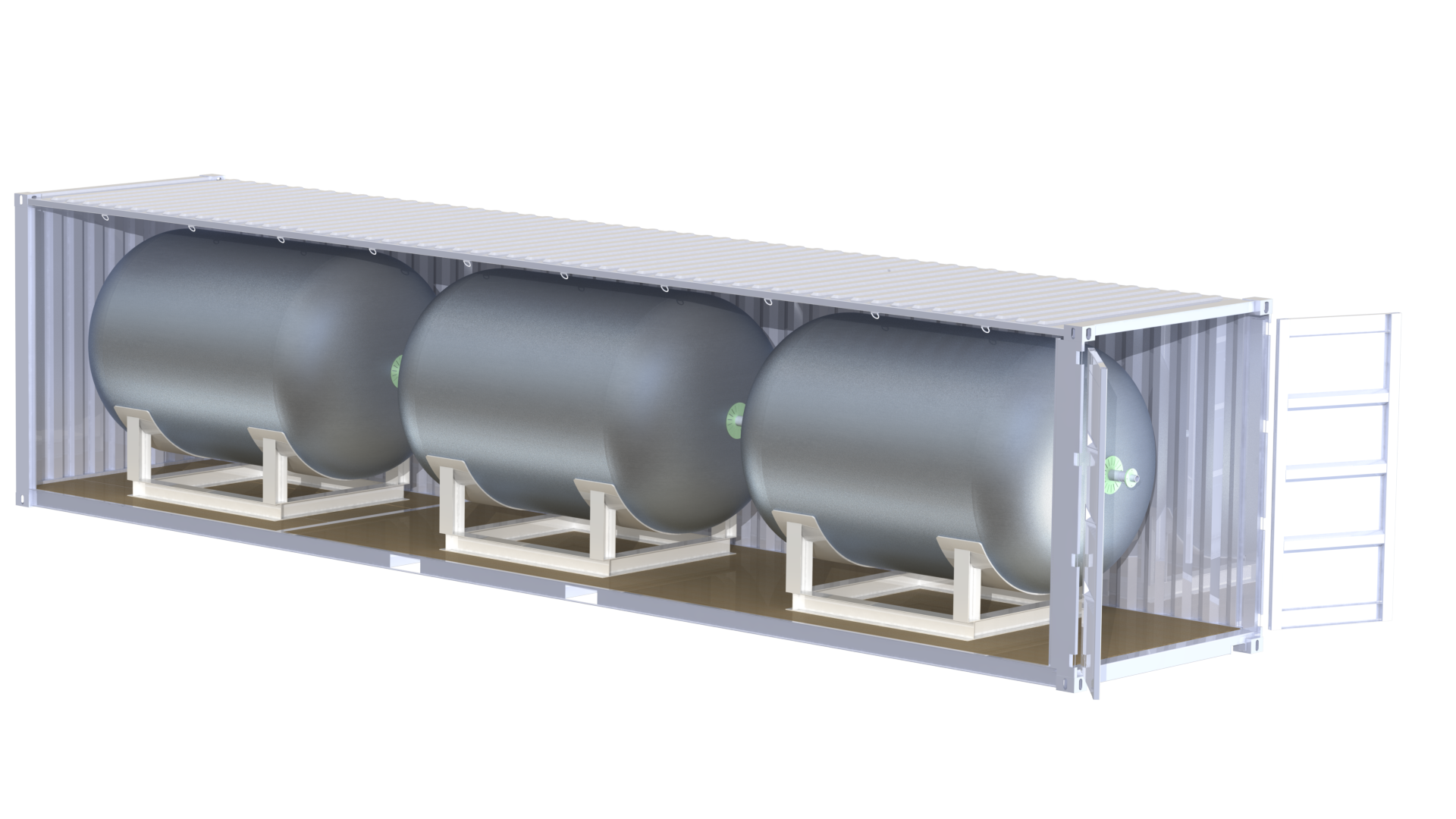

To safely transport P-LNG, three (3) of our proprietary type-4 tanks are installed inside of a standard intermodal shipping container to create a CanaGas Transport Module or CTM. Under UN designation such an intermodal transport module is called a Multi-Element Gas Container (MEGC). Our MEGCs or CTMs will carry up to 13 MT (625Mscf) of natural gas as P-LNG. Transportation costs are kept low as our CTMs will use the world’s existing intermodal infrastructure; trucks, trains & container ships. Container ships of all sizes may be chartered for the marine transport of P-LNG.

Due to the low cost of liquefaction, the capture and monetization of flared gas is made practical and feasible. Also NGL’s.

The same 100-Bar CTMs will second as fuel containers for ships or trains. At loading, P-LNG can be made easily from LNG or CNG with nominal energy input.

The same CTMs will also make small-scale biogas practical and feasible. Biogas can be economically produced from farms, feedlots, forestry operations, landfills and sewage treatment facilities where a tie-in to a natural gas pipeline is not available.

The same MCTMs can be used to transport natural gas in one direction, and liquid CO2 for sequestration in the other direction. No cleaning of the tanks is required at either end.

Similar CTMs at lower pressure will also transport liquid CO2, ethane, and ethylene; with little or no chilling.

At lower pressure still, CTMs will also safely transport methanol and ammonia.