P-LNG, A Low Cost Liquefaction Process

CanaGas is developing a new way to liquefy and transport natural gas using the world’s existing intermodal infrastructure. Using its proprietary type-4 pressure vessels (tanks) secured inside of ISO shipping containers, natural gas can be safely transported at a low cost by truck, train, and marine vessels.

Natural gas is easily liquefied into a two-phase state. The liquid portion is called pressurized-liquefied natural gas (P-LNG). At -50 C and 90 Bar pressure, a low-energy combination, natural gas will be fully liquefied. The cost to create P-LNG at this combination is approximately half that of conventional LNG.

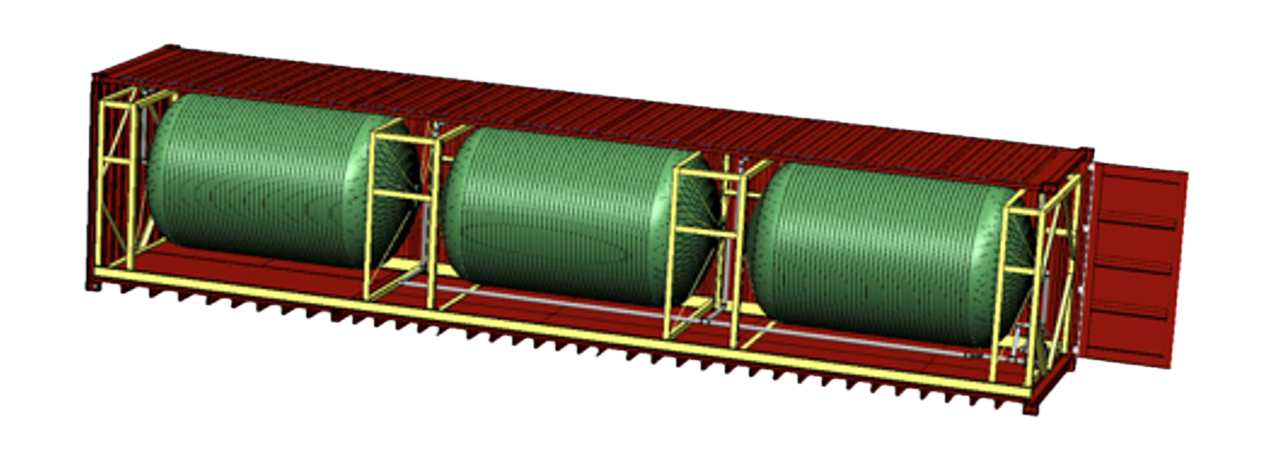

To safely transport P-LNG, several tanks are secured and well-insulated inside of a shipping container to form a high impact resistant CanaGas transport module (CTM).

A CTM will safely transport 11 metric tonnes (500 Mscf) of natural gas in a common 40-ft intermodal shipping container.

The CTM is a logistics disruptor as it will provide for the direct delivery of natural gas to industrial and commercial customers. The intermodal delivery of natural gas will bypass costly utility providers and LNG terminals. Where there is no gas provider, CTMs will deliver a new supply of natural gas to help generate commercial and social development.

The CTM may be used to rapidly discharge bulk gas to a distribution pipeline, or, be used as a fuel tank. Such fuel tanks may also be used to fuel ships by converting LNG into P-LNG.

Other gaseous fluids such as ethane, ethylene, CO2, methanol, & ammonia can also be transported as pressurized liquids but in lower pressure / lower cost tanks requiring very little energy.

A low-pressure CTM may also be used to transport heavy oil, without diluent as the oil is kept warm in well-insulated CTMs. By keeping the heavy oil warm, the viscosity remains low enough so that the oil may be pumped out on delivery. Such CTMs would be structurally enhanced to provide them with ultra-high impact resistance.